Contact us for more information!

Would you like to learn more about the XS Cloud? Simply contact us!

For you as a wholesaler with private labels, manually combining data deliveries from different manufacturers into a range involves a great deal of effort. This is exacerbated by inconsistent data deliveries from individual suppliers and increases the risk of overwriting and incorrect data. In addition to the manual summarisation, the individual adjustment of the data from the individual assortment to the overall assortment view also represents a challenge.

As a wholesaler, you receive data deliveries from the manufacturers that contain long texts for the products. These long texts are named by the manufacturer with an ID, often "LT1" or similar. However, several manufacturers now call their long texts "LT1". This means that the ID is no longer unique and there are complications when summarising the data. As a result, the data supplied by each manufacturer has to be checked and adapted at great expense. This is also very time-consuming.

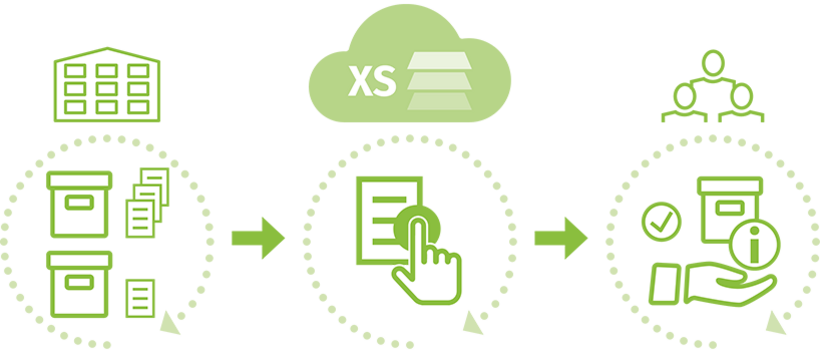

With Product Range Integration, you have the option of automatically merging these partial product ranges from manufacturers into a complete product range in your XS Cloud.

There is no need to manually check and adjust data content and IDs, as the intelligent module is based on individually configurable rules. For example, you can specify whether duplicate IDs - such as the ID "LT1" in the example above - should be overwritten, duplicated or assigned a new ID. With Product Range Integration, you save time, keep your data up to date at all times and can provide your customers with optimum article information and increase your sales opportunities.

You can easily expand your existing XS Cloud in the XS Supplier Portal area with the Product Range Integration.

All data is provided by the individual suppliers in a standardised DQR quality.

The data is summarised based on rules. These rules define whether data is duplicated or overwritten, for example.

Time saving

The automatic consolidation of all your private label manufacturers eliminates the need for time-consuming manual data maintenance.

Minimisation of the potential for errors

The risk of overwriting and incorrect data is minimised thanks to rule-based automation.

Reduced effort

Reduce the amount of manual processing and maintenance work thanks to the automated merging of product range data.

Always up-to-date data

The data is checked daily for changes. If changes are made, the assortment is re-integrated during the night and a new data record is provided.

Standardised data quality

After checking and approval, all data is available to you in standardised quality.

Automatic connection

After your approval, the data can be distributed to various systems such as the online shop, merchandise management or ausschreiben.de.

Learn more about our software solutions or contact us directly!

The new DQR 10.0 adopted by the associations ARGE Neue Medien, BVBS, DG Haustechnik and ZVSHK is valid from today.

Read more

To help you better understand the changes in the new DQR 10.0, we have created videos with explanations of the content.

Read more

The new DQR 10.0 has now been agreed between the associations ARGE Neue Medien, BVBS, DG Haustechnik and ZVSHK.

Read more

As the year draws to a close, we would like to thank you for your continued cooperation and trust in 2024.

Read more

The ETIM 10.0 release was published on 5 December 2024 and can be viewed in the Classification Management Tool (CMT).

Read more

The current economic situation poses considerable challenges for the HVAC industry. With a general decline in orders and increasing regulatory…

Read more